The growth of an enterprise is linked to the performance of its products/services which in turn is connected to efficient Product Lifecycle Management (PLM). Products manufacturing is a complex process and it requires many components or raw materials. Usually, the bill of materials explains where materials have been purchased from and how they have been put together.

However, it does not define the entirety of a product’s lifecycle. There exist many other aspects, such as design, distribution, sales, etc that need to be understood and managed. This is where PLM comes in.

What is PLM?

Product Lifecycle Management (PLM) is a systematic process of managing the complete journey of a product from cradle to grave. It involves how and when products are introduced in the market, starting from design and development to maturity and decline. This approach helps build better strategy and make decisions on marketing, and promotions, selling strategy, pricing as well as expansion and discontinuation plans. The process encompasses technology to help businesses create, capture, manage and leverage their products to help maximize profits.

PLM helps in cost-control, shortens development time, and gets products to market quickly.

The PLM strategy is most effective when supported by robust ERP software as it includes aspects of product development, supply chain, and Customer Relationship Management (CRM). With the help of different ERP modules, such as inventory management and supply chain management, it is possible to centralize information and connect all disparate but relevant aspects of a product’s lifecycle.

An effective PLM strategy makes it possible to reduce redundant and labour-intensive work, extend access to real-time, accurate data and bring all stakeholders right from design to product engineering and customer relationship management together into a single platform.

PLM is traditionally deployed by manufacturers who employ designers, engineers, marketers, and others to work with already established products, as well as develop new products.

Why Do Enterprises Need PLM?

According to Fortune Business Insights, the size of the PLM market in 2018 was $16.76 billion. It is expected to grow at a CAGR of 6.3% and reach $26.73 billion by 2026.

- To handle complexities between product design, supply chain, distribution, and customer feedback, and the impact of this on pricing. With the growing global competition driving prices down, regulations are constantly shifting, and your business needs quick-to-market, high-quality products to bring in profit.

- Information integrity and the efficiency of processes within the organization are dependent on each other, particularly in responding to a problem. With PLM, the information shared is clear, concise, and valid.

- Organizations struggle with disconnected systems, processes, and departments, along with issues of data quality and frequent order changes. Disparate software systems can escalate costs because of inefficiencies and slow commercialization of the product.

SAP PLM software helps organizations quickly develop and deliver the products that drive their businesses. It provides all-around support for all product-related processes from the start to the end of the product lifecycle. PLM provides businesses the capability to execute their crucial business functions using modular software that is built to work with other SAP or non-SAP applications.

The SAP PLM system extends essential access to engineers and designers to the information they require in real-time. The system simplifies project management by connecting the Computer-Aided Design (CAD) information with the bill of materials and other relevant data sources in the business, including the SAP ERP system. This way, it helps manage product-related data throughout every stage of the development lifecycle.

It also allows resources to gain insight into the external sources of information, such as the feedback on the latest products, the performance of products that are in use, and understanding limitations of processes, such as manufacturing.

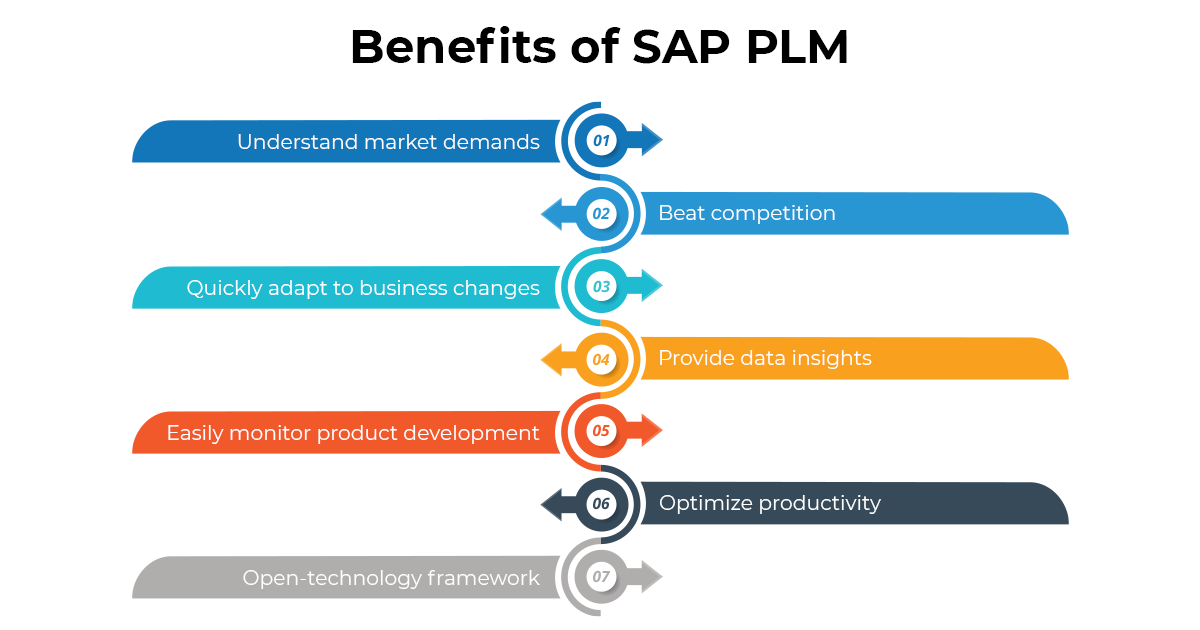

1. Businesses can keep abreast of market demands and then design innovative methods to develop products to beat the competition and gain strong market share.

2. Simultaneously modify relevant business processes involved in the development process. Introduce various quality checks and ensure compliance norms are adhered to.

3. Quickly adapt to business changes and be prepared to handle new opportunities in no time.

4. PLM provides ample insight into ongoing projects and gives insights into data that help make crucial business decisions. It comes with a flexible reporting structure as well as different types of analytics dealing with product quality, safety, portfolio management, and health hazards.

5. Ease of monitoring products through various developmental stages while keeping an eye on factors that affect production, such as time frame, resources required, and money.

6. It optimizes productivity through its role-based portal and enables content delivery thereby enhancing productivity.

7. SAP PLM provides an open-technology framework that delivers real-time data necessary for different processes like procurement, sales, manufacturing, etc.

With an updated and accurate bill of materials procured, SAP PLM results in:

- Improved production and development, and efficiency in engineering

- Tracking and eliminating mistakes during the engineering release process

- Reduced time to market

- Timely delivery of products

- Quality products.

Implementing SAP PLM can help enterprises develop an efficient strategy to ensure the timely release of products into the market. Gemini Consulting & Services can help you implement SAP PLM and achieve high efficiency. Contact us to understand how you can customize SAP PLM solutions to grow your business.

Implementing PLM and the Future

To grow amidst competition while retaining profit margins, attracting top talent, and producing the highest quality product possible using sustainable practices will be a constant for businesses. The right PLM application can help businesses handle these provided they are ready to invest in the technology required to get there.

With the Internet of Things (IoT) gaining impetus across industries, designers and engineers can easily leverage technology to obtain greater visibility into products and update products that are already out in the market. Now this empowers manufacturers with the ability to continue adding customer value throughout the product lifecycle.

SAP is also offering PLM systems in the cloud as software as a service (SaaS), thus making it easy for small companies to deploy and leverage its solutions.