In today’s competitive environment, successful product development hinges on effectively managing product structures and improving operational efficiency. These structures act as the blueprint for your product, detailing its components, connections, and configurations from inception to delivery. To accelerate time-to-market and boost productivity, manufacturers must collaborate with suppliers early in the development phase, and seamlessly integrate product data from different tools.

This post explores the key requirements for efficient product development—from design through to production and maintenance—and how Product Data Integration (PDI) enhances speed and efficiency.

The Enterprise Product Structure

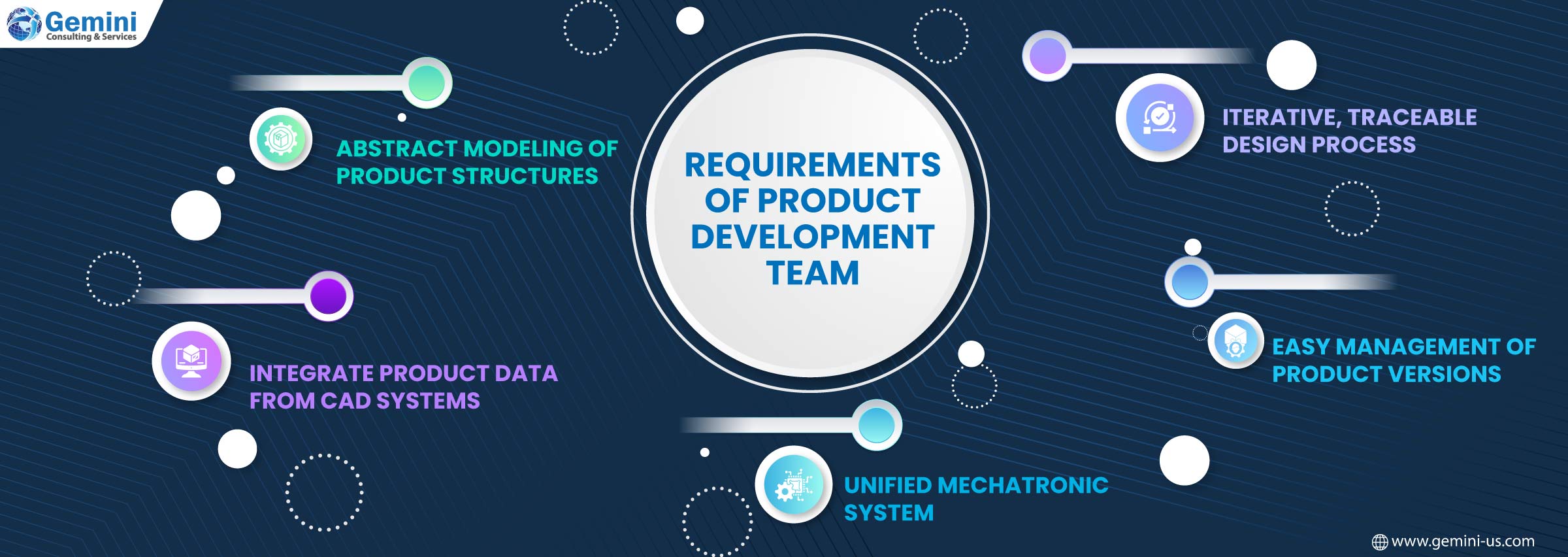

Product development teams often require solutions beyond the traditional Bill of Materials (BOM) features in SAP S/4HANA.

One of the primary needs is an SAP solution that allows for abstract modeling of product structures without creating a material master for each component—avoiding the typically costly processes involved in maintaining material masters. The product structure must serve as a central hub for different development disciplines, integrating product data from mechanical CAD systems, electrical CAD tools, or software development environments into a unified mechatronic system before the product is handed over to production.

Managing different product versions—such as color variations—should be feasible without relying on SAP’s advanced variant configuration (LO-VC) systems, which are complex and require specialized expertise. Product structures should also support 3D visualization for simulation purposes, enabling product managers to access and communicate product designs without needing specialized CAD systems.

Implementing an iterative, traceable design process with clear version management is also essential. To address these challenges, SAP introduced the Enterprise Product Structure (EPS), which provides a foundation for managing complex product data.

The success of EPS depends on extending its functionality, such as integrating with SAP’s Integrated Product and Process Engineering (iPPE) framework and ensuring robust performance when managing large product structures. Integration with common authoring systems and the ability to transfer the EPS to manufacturing BOMs for use in SAP S/4HANA systems across different global locations are crucial for EPS's effectiveness. SAP’s ongoing efforts to introduce Product Data Integration (PDI) and Intelligent Handover are key steps in this direction, offering a glimpse of how future SAP PLM implementations will meet customer needs with standard functionality.

Product Data Integration (PDI)

Released in May 2024, SAP PLM in the Cloud introduced PDI, a tool that enriches the Enterprise Product Structure with product data from authoring systems like mechanical CAD, electrical CAD, and software lifecycle management systems. With this, EPS becomes the central integration point for all product development processes.

Historically, SAP Engineering Control Center (SAP ECTR) has facilitated integration for on-premise and private cloud versions of SAP S/4HANA. Now, PDI bridges the gap for the public cloud version, providing seamless integration across all SAP systems.

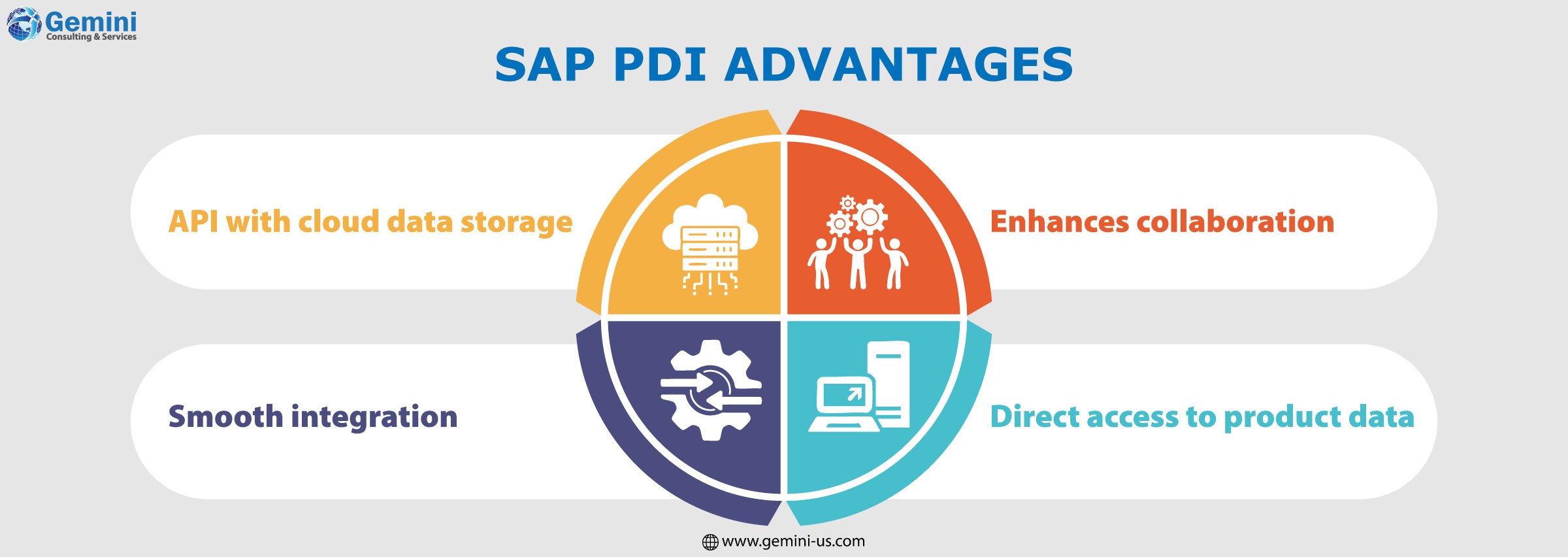

PDI functions as an API with cloud data storage, requiring a plugin for each authoring system to enable smooth integration. SAP partners are actively developing these plugins for popular authoring tools, making them available on the SAP Store. From a business perspective, PDI enhances collaboration between internal engineering teams and external suppliers by enabling direct access to structured product data, such as CAD assemblies, through EPS.

This direct collaboration contrasts with the traditional method of exporting unstructured data to suppliers, who then modify it and upload it back into the system. In the future, PDI could support hybrid collaboration scenarios, enabling seamless communication between internal and external teams using various tools and platforms.

Gemini Consulting & Services can help your enterprise leverage PDI to enhance product development and efficiency of engineering teams. Contact us to have a consultation with our SAP experts.

For example, a company might use SAP ECTR for internal product development and integrate PDI to collaborate efficiently with external suppliers, creating a hybrid end-to-end process. This opens up further possibilities for integrating Microsoft Office 365 solutions, Adobe Creative Suite, or even external PLM systems into the EPS framework.

The potential for PDI is vast, and as SAP continues to enhance these capabilities, the integration scenarios are expected to expand significantly, offering businesses even more efficient and flexible product development processes.