Today’s manufacturing processes require more than just efficiency; they must adapt to the challenges of a globalized world, prioritize environmental sustainability, and remain resilient in the face of disruptive events like pandemics and conflicts. Intelligent factories that embrace these principles can ensure sustainable and efficient manufacturing while complying with industry regulations and providing a safe working environment.

To achieve this, businesses need technology that can connect production processes both upstream with suppliers and downstream with customers. Additionally, a continuous flow of real-time information is essential to meet immediate customer demands, forecast future requirements, and fine-tune processes to stay ahead.

According to Mordor Intelligence, the digital transformation in the manufacturing market was valued at $263.93 billion in 2020 and is expected to reach $767.82 billion by 2026, with a compound annual growth rate (CAGR) of 19.48% from 2021 to 2026. This growth is driven by Industry 4.0 adoption in manufacturing, where digital technologies are enhancing, automating, and modernizing the entire process.

Cloud and Edge Computing play pivotal roles in Industry 4.0, elevating traditional Manufacturing Execution Systems (MES). They enable real-time data collection at the edge, provide flexibility in cloud resource allocation, and deliver more precise insights through Artificial Intelligence (AI) and Machine Learning (ML). These technologies offer benefits such as improved operational visibility, transparency, reliable insights, and timely decision-making.

User-friendly systems like SAP Digital Manufacturing Cloud (DMC) empower manufacturers to optimize their cloud infrastructure and performance, enhancing flexibility, visibility, and the exploration of new business models.

SAP Digital Manufacturing Cloud

SAP Digital Manufacturing Cloud creates intelligent factories with a strong focus on executing, analyzing, controlling, and integrating the entire manufacturing process. It operates as a cloud-based Manufacturing Execution System (MES), bridging the gap between production and business functions within the supply chain. This platform provides global visibility across all manufacturing facilities, seamlessly connecting top-level business systems to shop floor equipment. Manufacturers can not only execute manufacturing processes but also analyze manufacturing and business data, integrating applications cost-effectively while adhering to Industry 4.0 standards.

In addition to integrating manufacturing endpoints, SAP DMC serves as an extensible ERP system that integrates with handheld devices and augmented reality systems for desk-less workers. The bidirectional flow of information, including that of the extended supply chain and other business partners, enables real-time analysis of overall business performance.

How Businesses Approach SAP DMC Implementation?

The implementation of SAP DMC can be broken down into three core components.: SAP DMC for execution, insights integration, and the shop floor.

SAP DMC offers a comprehensive set of functionalities for seamless production execution. Join hands with Gemini Consulting & Services to leverage SAP DMC to simplify complex processes through user-friendly dashboards. Contact us if you are considering SAP DMC implementation for your manufacturing business.

SAP DMC Execution

This module boasts an intuitive user interface equipped with process-oriented features that facilitate planning, control, and monitoring of central production activities on the shop floor. It seamlessly integrates with central manufacturing and interconnected production solutions.

SAP DMC Insights

SAP DMC Insights leverages production insights from the enterprise level down to the plant level, enabling continuous improvement through SAP’s sense and respond software. Stakeholders can easily comprehend the priority, cost, and impact of driving improvements in existing processes and workflows. This module also enables the tracking of resources, personnel, machines, and the management of variations resulting from process changes. It provides industry-standard Key Performance Indicators (KPIs) to standardize KPI calculations across manufacturing plants.

SAP DMC Manufacturing Network

This module facilitates the detailed flow of information and process orchestration between the business, its customers, suppliers, and service providers. Integration with SAP S/4HANA enhances this module’s ability to provide an integrated environment across process and procurement levels, ensuring quality assurance.

Implementations can either be on-premise or integrated with SAP S/4HANA and other SAP ERP components using a Cloud Connector. The choice of integration depends on the industry classification—discrete industries with easily disassembled products (e.g., electronic appliances, automotive products) or process industries with final products that cannot be disassembled further (e.g., paper, chemicals, medicines, steel, and other materials). Different manufacturing units have specific master data and transactional data requirements, influencing SAP DMC implementations.

Once SAP DMC is operational, it contributes to a larger ERP system. Therefore, stakeholders should familiarize themselves with other SAP products like S/4HANA or SAP Extended Warehouse Management. Digital Manufacturing Cloud implementations often utilize extensions to integrate relevant business processes. The user interface employs public APIs, AI, and ML extensions for scenarios such as visual inspections in quality management. These extensions are created and preconfigured for use by SAP partners on the SAP Business Technology Platform.

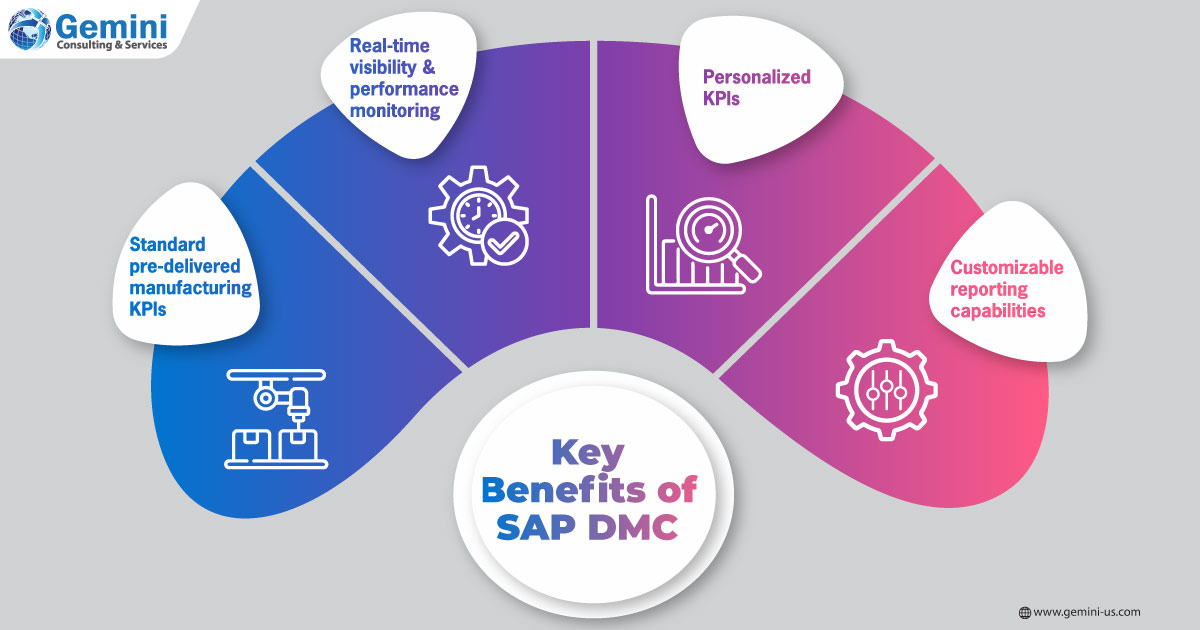

- All modules utilize out-of-the-box standard pre-delivered manufacturing KPIs, fed with execution data from ERP, Manufacturing Execution (ME), and DMC.

- Real-time visibility and performance monitoring of production processes are achievable at regional and geographic levels. This aids in performance comparisons between regions, plants within/across regions, and work centers and resources.

- Personalized KPIs offer visibility into underperforming regions, countries, and plants.

- Customizable reporting capabilities ensure optimal utilization of business assets.